For decades, the antimalarial drug artemisinin has been a lifeline for millions in tropical regions. Derived from the sweet wormwood plant (Artemisia annua), this sesquiterpene lactone compound has faced persistent challenges in traditional agricultural production – from seasonal variability to geopolitical supply chain vulnerabilities. Now, synthetic biology is rewriting the playbook through microbial biosynthesis, and the latest advancements suggest we're on the verge of an industrial transformation.

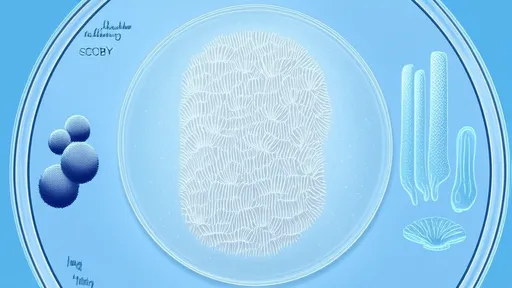

At the heart of this revolution lies the successful metabolic engineering of Saccharomyces cerevisiae and Escherichia coli to produce artemisinic acid, the immediate precursor to artemisinin. Early microbial platforms developed between 2006-2013 achieved titers around 25 g/L, but required extensive downstream chemical conversion. Today's engineered strains are breaking all previous records – with recent pilot-scale fermentations yielding over 100 g/L of artemisinic acid while simultaneously reducing byproduct formation through CRISPR-enabled pathway optimization.

The chassis organisms themselves are undergoing remarkable specialization. Chinese researchers recently unveiled a proprietary Yarrowia lipolytica strain featuring redesigned peroxisomes that enhance cytochrome P450 activity – addressing what was previously the bottleneck in the oxidation steps. Meanwhile, a joint EU-Singapore initiative has created a consortium of three microbial species that divide the biosynthetic labor, mimicking natural compartmentalization and achieving unprecedented pathway efficiency.

Downstream processing has seen equally transformative innovations. Traditional solvent extraction methods are being replaced by continuous flow chemistry systems that convert artemisinic acid to dihydroartemisinin in a single integrated process. The Sanofi-backed "Pharmalaboratory" in Lyon has demonstrated this approach can reduce production costs by 40% while eliminating several hazardous waste streams associated with conventional synthesis.

What makes the current generation of microbial factories truly disruptive is their metabolic flexibility. By introducing orthogonal genetic circuits, scientists can now dynamically reroute carbon flux in response to real-time fermentation conditions. This adaptive metabolism approach – pioneered by the Beijing Institute of Biotechnology – has shown particular promise in maintaining yield stability when using alternative feedstocks like lignocellulosic hydrolysates or food industry byproducts.

The regulatory landscape is evolving in tandem with these technical advancements. In 2023, the WHO issued preliminary guidelines for biologically synthesized artemisinin derivatives, while the European Pharmacopoeia added a dedicated monograph for microbially produced artemisinic acid. This regulatory clarity has spurred investment – with over $280 million in venture funding flowing into synthetic biology companies focused on terpenoid pharmaceuticals last year alone.

Environmental impact assessments tell a compelling story. Life cycle analyses comparing traditional agricultural production with microbial biosynthesis show reductions exceeding 65% in both water usage and land occupation. Perhaps more surprisingly, the carbon footprint of artemisinin produced in optimized bioreactors now rivals that of many small molecule drugs synthesized through conventional organic chemistry routes.

As these microbial platforms mature, they're enabling access to artemisinin analogs that were previously inaccessible at scale. Researchers at UC Berkeley recently used directed evolution to create strains producing C-10 modified artemisinin derivatives with improved pharmacokinetic profiles. Such innovations hint at a future where microbial factories serve as discovery platforms alongside production workhorses.

The transition hasn't been without challenges. Intellectual property disputes surrounding key pathway enzymes persist, and some traditional growers have raised concerns about market displacement. However, most industry observers see microbial production as complementary rather than competitive – especially given the growing global demand for artemisinin-based combination therapies (ACTs).

Looking ahead, the next five years will likely see the first fully automated, continuous artemisinin biomanufacturing facilities come online. With several companies now operating at commercial scale and prices for semi-synthetic artemisinin approaching parity with plant-derived material, what began as an academic demonstration of synthetic biology's potential has matured into one of the field's most tangible success stories. As climate change threatens traditional Artemisia cultivation regions, these microbial factories may soon become the world's most reliable source of this essential medicine.

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025